How to Implement Blockchain in Supply Chain: Expert Strategies

- BLOG

- Blockchain

- October 17, 2025

Blockchain is transforming supply chains by reducing costs, enhancing transparency, and accelerating operations. To implement blockchain effectively, start by identifying supply chain pain points, selecting the right platform and partners, and developing smart contracts. Then, run a pilot, then scale gradually while integrating with existing systems. We are going to explore everything about how to implement blockchain in supply chains effectively. You’ll learn practical steps, from identifying challenges to choosing platforms and partners.

Contents

- 1 How To Implement Blockchain In Supply Chain: Stepwise Guide

- 2 Transform Your Supply Chain Today!

- 2.1 Step 4: Design the Blockchain Network and Smart Contracts

- 2.2 Step 5: Develop a Detailed Implementation Plan

- 2.3 Step 6: Pilot Implementation

- 2.4 Step 7: Integrate Blockchain with Existing Systems

- 2.5 Step 8: Scale and Onboard Additional Stakeholders

- 2.6 Step 9: Continuous Monitoring and Optimization

- 3 Best Areas for Blockchain Implementation in Supply Chains

- 4 Advantages of Implementing Blockchain in Supply Chain

- 5 Real World Applications of Blockchain in Supply Chains

- 6 Common Challenges To Overcome To Implement Blockchain In The Supply Chain

- 7 Why Partner with Webisoft for Blockchain in Supply Chain

- 8 Transform Your Supply Chain Today!

- 9 Conclusion

- 10 FAQs on How To Implement Blockchain In Supply Chain

- 10.1 What are the key considerations for ensuring data accuracy on the blockchain?

- 10.2 How can blockchain improve collaboration among multiple supply chain partners?

- 10.3 What are the risks of integrating blockchain with existing ERP systems, and how can they be mitigated?

- 10.4 How do smart contracts handle exceptions or unexpected supply chain events?

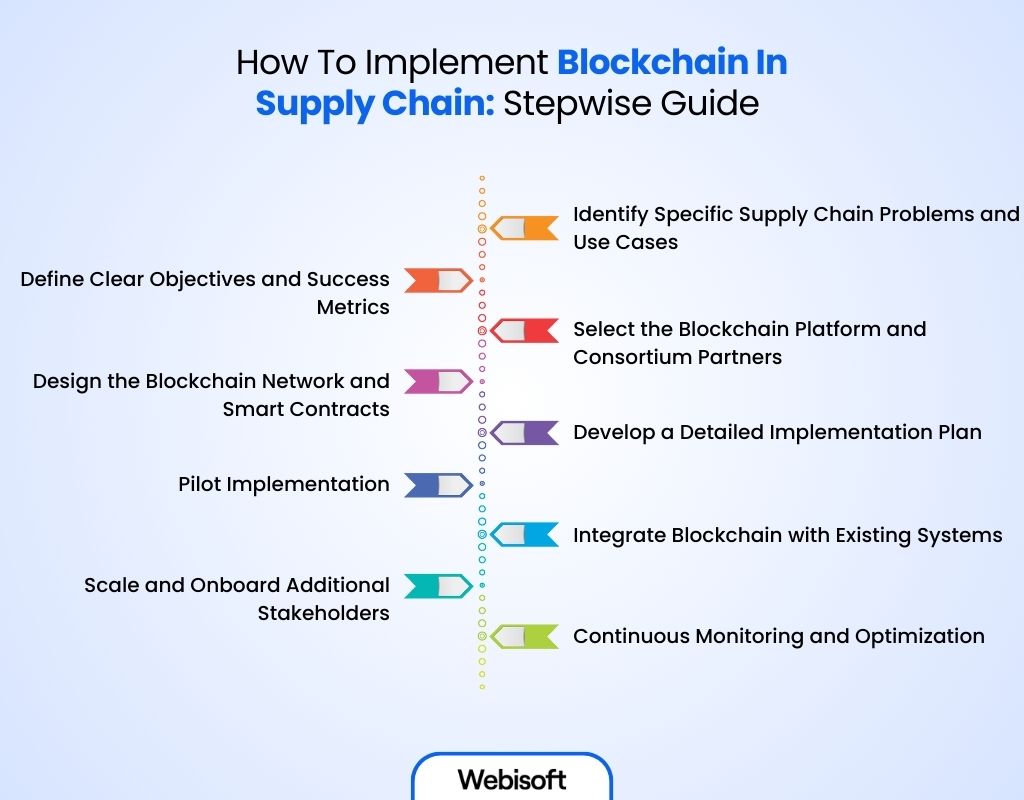

How To Implement Blockchain In Supply Chain: Stepwise Guide

Here is a comprehensive step-by-step guide to blockchain implementation in supply chains with practical strategies to improve operational efficiency.

Here is a comprehensive step-by-step guide to blockchain implementation in supply chains with practical strategies to improve operational efficiency.

Step 1: Identify Specific Supply Chain Problems and Use Cases

Start by pinpointing exact problems within your supply chain.

Lack of Transparency and Visibility

You often struggle to get real-time, accurate information about product status, location, and conditions as goods move through multiple parties. This opacity can cause delays, errors, and disputes.

Traceability Challenges

Tracking the origin and journey of products is difficult, especially for complex goods with many components or raw materials sourced globally. This makes it hard to verify authenticity or compliance.

Fraud and Counterfeiting

Counterfeit goods or falsified documentation can enter the supply chain, harming brand reputation and consumer safety. This is common in industries like pharmaceuticals, luxury goods, and food.

Data Silos and Manual Errors

Supply chain data is often fragmented across different systems and stakeholders, leading to inconsistencies, manual data entry errors, and delays in information sharing.

Inefficient Processes and High Costs

Administrative overhead from paperwork, intermediaries, and slow reconciliation processes increases costs and reduces efficiency.

Step 2: Define Clear Objectives and Success Metrics

In this stage of how to implement blockchain in supply chain, it’s important to set clear objectives and success metrics to guide your blockchain implementation. Your objectives should be concrete and relevant to your current challenges. Common goals include:

- Improving transparency and traceability

- Reducing fraud and counterfeiting

- Enhancing efficiency

- Ensuring regulatory compliance and sustainability

- Increasing real-time visibility

Once objectives are clear, establish key performance indicators (KPIs) that will help you evaluate blockchain’s impact. Examples include:

| Traceability Rate | Percentage of products fully traceable on blockchain. |

| Reduction in Fraud Incidents | Number of counterfeit cases detected or prevented. |

| Process Time Reduction: | Time saved in documentation, payments, or inventory updates. |

| Cost Savings: | A decrease in administrative or operational costs due to blockchain automation. |

| Stakeholder Adoption Rate: | Percentage of supply chain partners actively using the blockchain system. |

| Compliance Accuracy: | Number of compliance violations before and after blockchain implementation. |

Ensure that your objectives resonate with all key participants in your supply chain, including suppliers, logistics providers, regulators, and customers. This alignment improves collaboration and smooth adoption.

Step 3: Select the Blockchain Platform and Consortium Partners

You should carefully assess blockchain platforms based on your supply chain’s specific needs, considering factors such as scalability, privacy, smart contract capabilities, and integration ease.

Permissioned vs. Public Blockchains:

For supply chains, permissioned (private) blockchains like Hyperledger Fabric, R3 Corda, or IBM Blockchain are often preferred because they restrict access to authorized participants, ensuring data privacy and control. Public blockchains like Ethereum offer transparency but may introduce higher costs and slower transaction speeds.

Other Key Features to Look For:

- Smart Contracts to automate processes such as payments and compliance.

- Distributed Ledger for immutable, tamper-proof records.

- Validation Mechanisms that require consensus among participants before data is recorded.

- IoT Integration capabilities for real-time tracking of goods and conditions.

- Modular Architecture to allow phased implementation and integration with existing ERP or SCM systems

Once you have selected the blockchain platform, the next step is to identify and engage consortium partners. Blockchain’s strength in supply chains lies in collaboration, so you must bring together all relevant stakeholders. For faster and professional guidance on how to implement blockchain in supply chain, contact a technology solutions provider specializing in blockchain development and supply chain optimization.

Transform Your Supply Chain Today!

Contact Webisoft for Expert Blockchain Implementation Support

Step 4: Design the Blockchain Network and Smart Contracts

Designing the blockchain network and smart contracts is a critical step to ensure your supply chain operates transparently, efficiently, and securely. Begin by structuring the blockchain network to connect all authorized participants. Such as suppliers, manufacturers, logistics providers, regulators, and retailers, with the use of a permissioned blockchain. Next, develop smart contracts to automate key supply chain processes. These self-executing contracts trigger actions. Such as order confirmations, shipment tracking, payments, and compliance verifications based on predefined conditions. You can reduce manual errors, speed up transactions, and enforce compliance automatically. Key aspects to focus on include:

- Modular Network Design: Separate transactions by causality to simplify processing and reduce barriers for participants.

- Integration with IoT Devices: Capture real-time data that automatically updates the blockchain.

- Data Layer and Access Control: Define data structures for assets, transactions, and events, and implement role-based permissions.

- Transparency and Immutability: Ensure all recorded data is timestamped and tamper-proof, providing a single source of truth.

Step 5: Develop a Detailed Implementation Plan

To ensure a smooth blockchain rollout in your supply chain, create a structured project timeline divided into clear phases. Here is an example of what it should look like.

- Assessment (2-3 months): Document current workflows, identify integration points with existing systems, and gather detailed requirements.

- Development (4-6 months): Set up the blockchain infrastructure and develop smart contracts tailored to your supply chain processes.

- Integration & Testing (3-4 months): Connect the blockchain solution with your ERP and IoT systems, then conduct pilot testing to validate functionality and performance.

Now, each team role must connect and collaborate effectively. To ensure the best results, you can collaborate with Webisoft for expert guidance and seamless blockchain development services. Our team will work closely with you to align your project with business goals and technical requirements.

Step 6: Pilot Implementation

The next step is to conduct a pilot implementation. A pilot allows you to test the blockchain solution on a smaller scale, identify potential issues early, and gather valuable feedback before full-scale deployment

- Begin by selecting a limited scope for the pilot, such as tracking one product line or a specific shipment route. It helps to minimize risks.

- Configure blockchain nodes and deploy smart contracts that automate key supply chain processes.

- Train pilot participants on using the blockchain interface to ensure smooth adoption.

- During the pilot, run real transactions, capture data, and monitor metrics like transaction speed, data accuracy, and user feedback.

Step 7: Integrate Blockchain with Existing Systems

Once the pilot is successful, you have to integrate blockchain with your existing systems. Begin by assessing your current IT infrastructure, including ERP, CRM, and IoT platforms. Use APIs or middleware to enable secure, real-time data exchange between blockchain nodes and these systems. Develop connectors that translate data formats and protocols to ensure compatibility. Implement data validation and synchronization mechanisms to maintain consistency across platforms.

Step 8: Scale and Onboard Additional Stakeholders

It’s time to grow the blockchain network by adding more people involved in the supply chain, like suppliers, manufacturers, and retailers. First, identify who needs to join and create easy-to-follow instructions and training to help them get started. Set clear rules and rewards to encourage everyone to participate actively. Make sure their existing systems can connect smoothly with the blockchain, and provide technical help if needed. Keep protecting data and following regulations as more participants join.

Step 9: Continuous Monitoring and Optimization

After scaling the blockchain network, continuous monitoring and optimization are essential to keep the system running smoothly and efficiently. Regularly track key performance indicators like transaction speed, data accuracy, and user activity to spot issues early. Use monitoring tools to detect errors, delays, or security risks and fix them quickly. Gather feedback from all participants to understand their challenges and improve the system accordingly. Update smart contracts and processes as needed to adapt to changing business needs or regulations.

Best Areas for Blockchain Implementation in Supply Chains

Blockchain can help make supply chains clearer, safer, and faster. Here are key areas where it works well:

Blockchain can help make supply chains clearer, safer, and faster. Here are key areas where it works well:

Product Provenance and Traceability

Blockchain records every step a product takes, from raw materials to the customer. This helps businesses and consumers know exactly where a product comes from and how it was handled.

Counterfeit Prevention and Authenticity

By securely storing product information, blockchain makes it easy to verify if something is genuine. This protects brands and customers from fake or unsafe goods.

Payments and Invoicing

Automating payments and invoices with blockchain reduces errors and speeds up the process. This means fewer delays and less paperwork between companies.

Compliance and Audits

Blockchain keeps a permanent, unchangeable record of rules and certifications being met. This makes it easier for companies to prove they follow laws and standards during audits.

Inventory and Shipment Tracking

With blockchain linked to tracking devices, companies can see where their products are in real time. This improves delivery accuracy and helps prevent lost or stolen items.

Sustainability and Ethical Sourcing

Blockchain can verify that products are made using fair labor and eco-friendly methods. This builds trust with consumers who care about responsible sourcing.

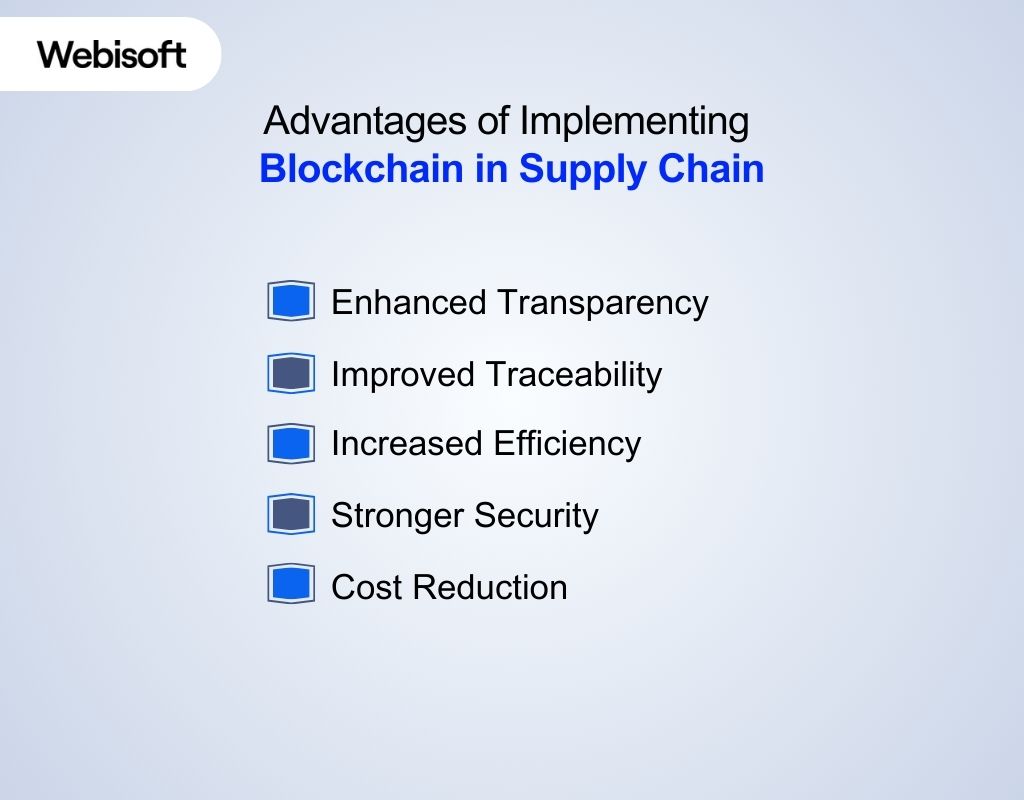

Advantages of Implementing Blockchain in Supply Chain

Blockchain adoption in supply chains is rapidly reshaping operations by improving transparency, security, and efficiency. Here are key benefits backed by data and real-world impact:

Blockchain adoption in supply chains is rapidly reshaping operations by improving transparency, security, and efficiency. Here are key benefits backed by data and real-world impact:

Enhanced Transparency

Blockchain provides a shared, immutable ledger visible to all authorized parties. This transparency reduces disputes and builds trust.

Improved Traceability

Track products from origin to delivery with tamper-proof records. In industries such as pharmaceuticals and food, blockchain enhances the ability to verify authenticity and quickly trace affected items during recalls. For example, Walmart’s blockchain pilot with IBM reduced the time required to trace mangoes from seven days to just over two seconds, demonstrating how blockchain can drastically speed up investigations and improve consumer safety.

Increased Efficiency

Automated workflows and smart contracts cut manual errors and speed processes like payments and compliance. Blockchain can reduce documentation processing time by 85%, significantly lowering operational costs.

Stronger Security

Cryptographic protections safeguard sensitive data, making unauthorized changes nearly impossible. This reduces fraud risk and enhances data integrity across the supply chain1.

Cost Reduction

By eliminating intermediaries and automating tasks, blockchain lowers administrative overhead and operational expenses. Studies show supply chain costs can drop by 20-30% after blockchain adoption.

Real World Applications of Blockchain in Supply Chains

Here are notable real-world use cases illustrating its impact:

Here are notable real-world use cases illustrating its impact:

Walmart and IBM Food Trust:

Walmart uses blockchain to track produce from farm to shelf, enabling recall times to drop from days to seconds. This system improves food safety, reduces waste, and boosts consumer confidence by providing transparent product origins.

Ford’s Automotive Blockchain Consortium:

Ford tracks and verifies auto parts’ authenticity and origin through blockchain. The platform records assembly details, certifications, and shipping data, helping combat counterfeit parts and streamline supplier collaboration with smart contracts.

Maersk TradeLens for Container Logistics:

Maersk and IBM launched TradeLens to digitize shipping documentation and shipment status. This blockchain platform connects ports, customs, freight forwarders, and carriers, speeding up container logistics and increasing visibility.

AgriDigital Grain Supply Chain:

AgriDigital’s blockchain platform digitizes grain transactions in Australia, automating delivery receipts and payments. The pilot reduced administrative overhead by 40% and cut dispute resolution time by 80%, enhancing transparency from farmers to buyers.

BMW PartChain:

BMW uses blockchain with IoT to track millions of parts globally. RFID tags record shipment data on a shared ledger, reducing counterfeit risk, improving customs clearance, and enabling just-in-time delivery for manufacturing

Common Challenges To Overcome To Implement Blockchain In The Supply Chain

Professionals often encounter these critical challenges when deploying blockchain in supply chains, along with effective solutions:

Professionals often encounter these critical challenges when deploying blockchain in supply chains, along with effective solutions:

Data Standardization Across Systems

Organizations frequently struggle with diverse legacy systems and inconsistent data formats. Implement industry-wide standards such as GS1 and develop middleware to harmonize data before blockchain integration.

Maintaining Data Confidentiality

Balancing transparency while protecting sensitive commercial information is complex. Utilize permissioned blockchains with zero-knowledge proofs and granular access controls to secure confidential data.

Scalability for High Transaction Volumes

Blockchain networks can experience performance degradation under heavy transaction loads. Employ hybrid architectures combining on-chain records with off-chain mechanisms like state channels or sidechains to ensure scalability.

Stakeholder Adoption and Engagement

Securing buy-in from diverse partners is often challenging due to perceived costs and complexity. Demonstrate clear value propositions, streamline user interfaces, and establish incentive models to drive adoption.

Smart Contract Maintenance and Upgradability

Immutable smart contracts pose difficulties for post-deployment modifications. Design modular, upgradeable smart contracts supported by comprehensive testing and robust version control processes.

Why Partner with Webisoft for Blockchain in Supply Chain

When your supply chain demands secure, transparent, and efficient blockchain solutions, Webisoft offers the expertise and proven approach to make it a reality.

When your supply chain demands secure, transparent, and efficient blockchain solutions, Webisoft offers the expertise and proven approach to make it a reality.

Expertise You Can Count On

Our team combines deep blockchain knowledge with supply chain experience, delivering solutions that are innovative, secure, and tailored to your needs.

Customized Solutions for Your Business

We understand that no two supply chains are the same. That’s why we build blockchain solutions designed specifically to solve your unique challenges and boost efficiency.

Seamless System Integration

Integrating new technology shouldn’t disrupt your operations. We ensure smooth, hassle-free integration with your current systems for continuous performance.

Ongoing Support and Growth

Our commitment goes beyond launch. We provide ongoing support, updates, and maintenance to keep your blockchain solution running smoothly as your business evolves.

Transform Your Supply Chain Today!

Contact Webisoft for Expert Blockchain Implementation Support

Conclusion

Implementing blockchain in supply chain strengthens collaboration and improves decision-making by providing a single source of truth. It drives operational excellence and helps companies respond swiftly to disruptions while maintaining agility. Successfully learning how to implement blockchain in supply chain requires careful planning, stakeholder alignment, and ongoing refinement to unlock its full value. As supply chains become more complex, blockchain offers a reliable foundation for innovation and resilience.

FAQs on How To Implement Blockchain In Supply Chain

What are the key considerations for ensuring data accuracy on the blockchain?

Implement strong IoT or sensor integration for real-time data capture, combined with validation rules and consensus mechanisms to prevent false or tampered information from entering the blockchain.

How can blockchain improve collaboration among multiple supply chain partners?

Blockchain provides a single source of truth, enabling all parties to access the same verified data. Clear governance models and role-based permissions facilitate trust and coordinated decision-making.

What are the risks of integrating blockchain with existing ERP systems, and how can they be mitigated?

Data inconsistency and system incompatibility are common risks. Mitigate these by thorough system audits, using middleware for data translation, and phased integration with extensive testing.

How do smart contracts handle exceptions or unexpected supply chain events?

Smart contracts are designed for predefined conditions. For exceptions, implement fallback procedures, off-chain arbitration mechanisms, or manual overrides to manage unplanned scenarios.