Machine Learning in Oil and Gas Industry: Use Cases & Risks

- BLOG

- Artificial Intelligence

- January 26, 2026

Machine learning in oil and gas industry refers to using data-driven models to analyze operational, geological, and production data. Traditional workflows struggle with fragmented systems, delayed insights, and the scale of seismic, well log, and sensor data.

Machine learning addresses this gap by processing these datasets at scale across exploration, drilling, production, and maintenance. Unlike general automation, machine learning continuously learns from historical and real-time data, improving accuracy as operating conditions and asset behavior change.

This article explains what machine learning means in practical terms, how it works inside oil and gas operations, and where it delivers measurable value. We will also discuss real-world use cases, data requirements, risks, and how companies apply machine learning across the oil and gas value chain.

Contents

- 1 What Machine Learning Means in the Oil and Gas Industry

- 2 How Machine Learning Works Inside Oil and Gas Operations

- 3 Key Applications of Machine Learning in Oil and Gas

- 4 Real World Use Cases of Machine Learning in the Oil and Gas Industry

- 5 Data and Infrastructure Requirements for Machine Learning in Oil and Gas

- 6 Challenges and Risks of Machine Learning in Oil and Gas Industry

- 7 Build reliable machine learning systems for oil and gas with Webisoft.

- 7.1 Cultural Resistance to Model-Driven Decisions

- 7.2 High Initial Investment and ROI Pressure

- 7.3 Cybersecurity Exposure and Operational Risk

- 7.4 Operational and Environmental Risk Amplification

- 7.5 Erroneous Model Outputs and Misinterpretation

- 7.6 Loss of Institutional Knowledge

- 7.7 Ethical and Legal Considerations

- 8 How Webisoft Delivers Machine Learning in Oil and Gas Industry

- 9 Build reliable machine learning systems for oil and gas with Webisoft.

- 10 Conclusion

- 11 FAQs

- 11.1 1. Can machine learning work with limited historical oil and gas data?

- 11.2 2. Is machine learning suitable for small or mid-sized oil and gas operators?

- 11.3 3. How is machine learning different from traditional oilfield analytics?

- 11.4 4. Can machine learning models adapt to different basins or fields?

- 11.5 5. What skills should oil and gas teams develop for machine learning adoption?

What Machine Learning Means in the Oil and Gas Industry

Machine learning in oil and gas industry refers to the practical use of advanced computational models that learn from historical and real-time data to make predictions, uncover patterns, and automate complex decisions across the energy value chain.

Unlike traditional statistical methods, machine learning applications in oil and gas can handle massive, high-velocity, and heterogeneous data. Thus it turns it into actionable insights that improve operational outcomes. According to an industry study, machine learning delivers value across exploration, drilling, production, and reservoir characterization.

In exploration, seismic processing, and subsurface interpretation generate terabytes of data. Models such as convolutional neural networks analyze seismic images to identify geological features and estimate reservoir properties, reducing interpretation time.

In reservoir management, machine learning supports real-time performance monitoring. Operators can adjust extraction strategies dynamically to maximize recovery while managing production decline. These capabilities improve decision accuracy under changing reservoir conditions.

Beyond upstream operations, machine learning use cases in oil and gas extend into midstream activities. Pipeline monitoring and leak detection models learn normal operating patterns and flag anomalies early. This enables intervention before failures escalate.

At its core, machine learning for oil and gas operations transforms raw operational data into decision-ready outputs. It helps companies improve efficiency, reduce costs, and enhance safety where traditional methods struggle to scale.

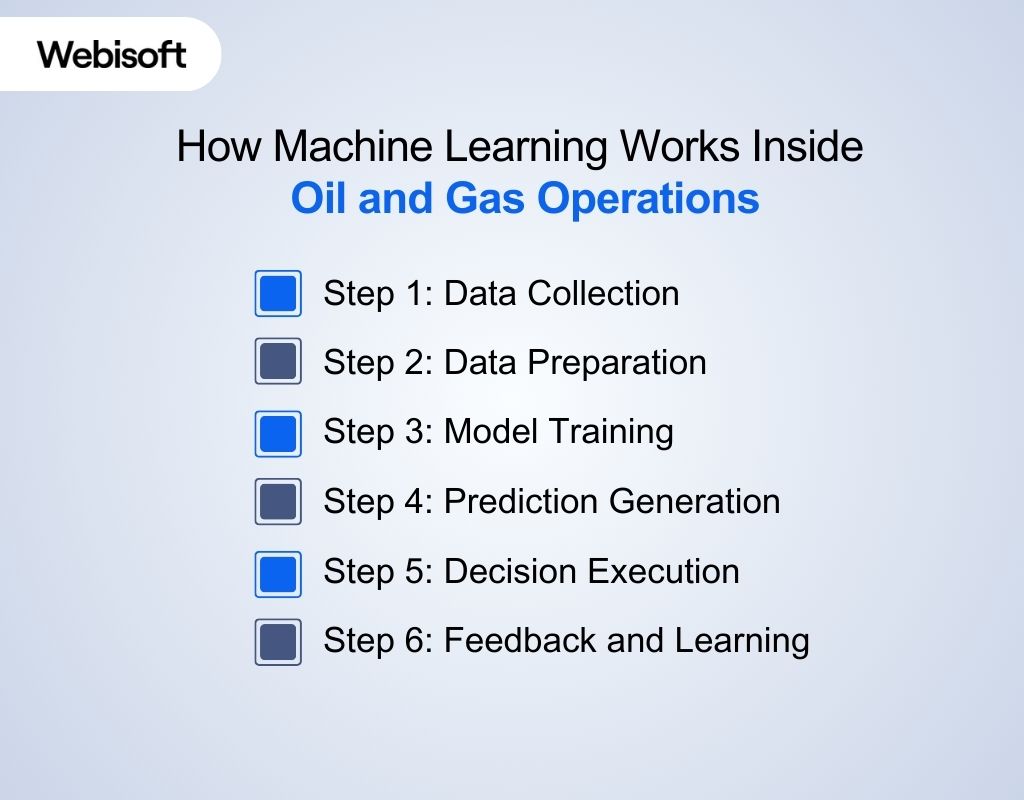

How Machine Learning Works Inside Oil and Gas Operations

Machine learning systems in oil and gas follow a structured operational workflow. This workflow converts raw field data into predictions and actions that guide daily engineering decisions. At its core, machine learning in oil and gas industry connects data, models, and operational control in a continuous feedback loop

Machine learning systems in oil and gas follow a structured operational workflow. This workflow converts raw field data into predictions and actions that guide daily engineering decisions. At its core, machine learning in oil and gas industry connects data, models, and operational control in a continuous feedback loop

Data Collection

↓

Data Preparation

↓

Model Training

↓

Prediction Generation

↓

Decision Execution

↓

Feedback and Learning

Step 1: Data Collection

Operations generate massive data volumes from seismic surveys, well logs, drilling sensors, production systems, and pipeline monitoring tools. This data includes pressure, temperature, vibration, flow rates, geological attributes, and equipment performance signals. Reliable data collection is the foundation for all machine learning applications in oil and gas.

Step 2: Data Preparation

Raw field data often contains noise, gaps, and inconsistent timestamps. Engineers clean, normalize, and align datasets across depth, time, and assets. This step transforms raw measurements into structured inputs suitable for modeling.

Step 3: Model Training

Historical datasets are used to train models such as neural networks, random forests, and gradient boosting algorithms. Models learn how input variables relate to outcomes like production rates, drilling risks, or equipment behavior. Training quality directly affects prediction reliability in machine learning use cases in oil and gas.

Step 4: Prediction Generation

Trained models generate forecasts based on new or real-time data. Predictions may include hydrocarbon probability, optimal drilling parameters, failure likelihood, or production decline trends. These outputs support faster and more informed operational decisions.

Step 5: Decision Execution

Engineers use model outputs to adjust drilling settings, optimize injection strategies, or plan maintenance activities. In advanced setups, control systems apply these adjustments automatically within predefined safety limits. This enables consistent execution across machine learning for oil and gas operations.

Step 6: Feedback and Learning

Operational outcomes are fed back into the system after actions are taken. Models retrain using updated data to reflect changing reservoir conditions and equipment behavior. This continuous loop improves accuracy and operational alignment over time.

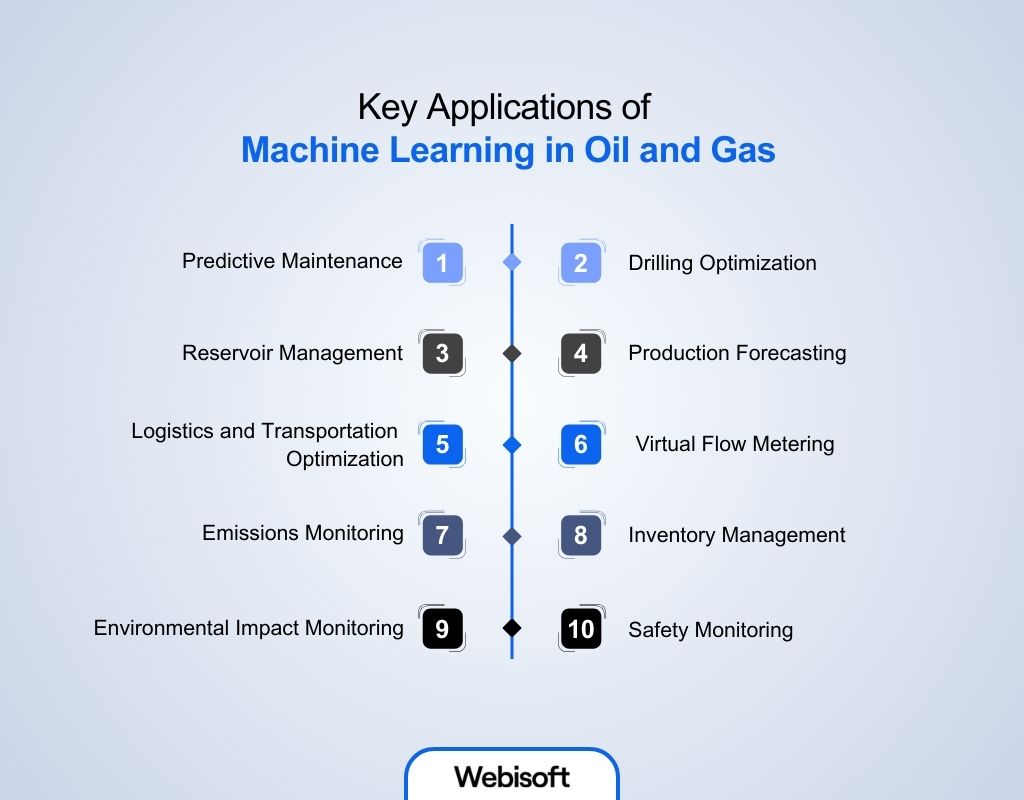

Key Applications of Machine Learning in Oil and Gas

Machine learning supports oil and gas operations by handling repetitive, data-intensive tasks that require speed, consistency, and precision. Across the value chain, machine learning in oil and gas industry turns operational data into predictions, recommendations, and automated adjustments that improve performance and control risk.

Machine learning supports oil and gas operations by handling repetitive, data-intensive tasks that require speed, consistency, and precision. Across the value chain, machine learning in oil and gas industry turns operational data into predictions, recommendations, and automated adjustments that improve performance and control risk.

Predictive Maintenance

Sensors installed on pumps, compressors, and pipelines generate continuous condition data. Machine learning applications in oil and gas analyze vibration, pressure, and temperature trends to detect early signs of equipment failure.

This allows maintenance teams to act before breakdowns occur, reducing downtime and repair costs. Also, research shows machine learning improves maintenance efficiency, cuts downtime, lowers costs, and increases safety.

Drilling Optimization

Drilling operations produce high-frequency data from surface and downhole sensors. Models analyze this data to predict drilling efficiency, equipment wear, and instability risks.

Machine learning use cases in oil and gas enable real-time parameter adjustments that reduce non-productive time and drilling incidents. Research review focused on ML applications in drilling, including pattern analysis of drilling data and optimization.

Reservoir Management

Reservoir teams rely on seismic, geological, and production data to understand subsurface behavior. Machine learning models integrate these datasets to improve reservoir characterization accuracy.

Predictions support better recovery planning and long-term production optimization. Research also shows how ML methods assist reservoir engineering tasks such as predictive modelling and scheme optimization.

Production Forecasting

Historical production data is used to train models that predict future output trends. These forecasts help teams plan field development, manage decline, and allocate capital more effectively. Accurate predictions reduce uncertainty in operational and investment decisions.

Logistics and Transportation Optimization

Midstream operations involve complex scheduling and routing decisions. Machine learning models analyze flow rates, demand patterns, and infrastructure constraints. This improves pipeline utilization, delivery efficiency, and transportation planning.

Virtual Flow Metering

Virtual flow metering replaces physical meters using data-driven flow predictions. Machine learning models estimate flow rates from pressure, temperature, and choke data. Machine learning for oil and gas operations improves measurement accuracy in remote locations. This reduces instrumentation costs while maintaining production visibility.

Emissions Monitoring

Environmental data from sensors, inspections, and monitoring systems is continuously analyzed. Machine learning detects abnormal emissions patterns and leakage events early. These insights support rapid mitigation and regulatory compliance. They also improve environmental transparency across operations.

Inventory Management

Operations require precise availability of spare parts, chemicals, and equipment. Predictive models estimate future inventory needs based on usage patterns and operational activity. This reduces excess stock while preventing costly supply delays.

Environmental Impact Monitoring

Environmental data from sensors, inspections, and reports is continuously analyzed. Machine learning identifies abnormal emissions, leaks, and compliance risks early. This supports mitigation planning and regulatory adherence.

Safety Monitoring

Operational data from equipment and wearable devices is used to assess workplace risk. Machine learning for oil and gas operations detects unsafe conditions before incidents occur. This improves safety outcomes and supports proactive risk management.

Real World Use Cases of Machine Learning in the Oil and Gas Industry

Major energy companies are increasingly turning to machine learning in oil and gas industry as part of broader digital transformation and operational efficiency efforts. According to StartUS insight data, AI and machine learning rank among the top 10 innovation trends shaping exploration, production, and operational workflows globally.

Major energy companies are increasingly turning to machine learning in oil and gas industry as part of broader digital transformation and operational efficiency efforts. According to StartUS insight data, AI and machine learning rank among the top 10 innovation trends shaping exploration, production, and operational workflows globally.

These technologies optimize predictive maintenance, seismic interpretation, and real-time analytics across the value chain.

Saudi Aramco’s Advanced Analytics for Exploration

Saudi Aramco invests heavily in technology, innovation, and digitization to enhance exploration and reservoir understanding. The company uses aerial data and sensor streams to feed ML models that support subsurface analysis and early detection of anomalies in oil fields.

This improves drilling site selection and reduces geological uncertainty in exploration and expansion programs. By automating seismic data processing and model updating, engineers gain near-real-time insights into reservoir behavior. These tools contribute to faster decision cycles and improved predictive accuracy in upstream activities.

Chevron’s Integrated Data and Production Insight

Chevron applies machine learning by integrating deep sensor data with simulation outputs and mechanical earth models. At Chevron Canada, data from fiber-optic and acoustic sensors improves drilling performance and reservoir predictions.

ML-driven analytics help convert raw data into refined operational forecasts that guide production and maintenance actions. These models enhance efficiency, support sustainability goals, and reduce risk through better operational foresight.

Startup-Led Innovation Across the Sector

StartUs Insights reports on 197 global machine learning startups driving new solutions for predictive analytics, subsurface modeling, and pipeline monitoring. These companies work with operators to deliver tailored tools that improve drilling execution, automate predictive workflows, and monitor asset health. Such innovations amplify industry capabilities beyond traditional vendor systems and reinforce data-driven operational models.

Measurable Impact on Efficiency and Strategy

Across the oil and gas sector, ML-enabled systems are helping companies respond to complex operational challenges with data-driven decisions. From predictive maintenance to seismic interpretation optimization, organizations are reducing cost and variability while improving forecasting accuracy. This shift toward automated data interpretation and advanced analytics supports strategic planning in competitive global markets.

Data and Infrastructure Requirements for Machine Learning in Oil and Gas

Deploying machine learning in the oil and gas industry requires a strong data and infrastructure foundation that supports large-scale, distributed, and time-sensitive operations. Data and Infrastructure Requirements for Machine Learning in Oil and Gas are driven by the need to process high data volumes from remote assets while enabling both real-time analytics and historical analysis:

Deploying machine learning in the oil and gas industry requires a strong data and infrastructure foundation that supports large-scale, distributed, and time-sensitive operations. Data and Infrastructure Requirements for Machine Learning in Oil and Gas are driven by the need to process high data volumes from remote assets while enabling both real-time analytics and historical analysis:

Data Sources and Integration

Successful machine learning depends on consistent, accurate, and complete operational data. Machine learning applications in oil and gas rely on seismic surveys, drilling logs, SCADA systems, production databases, and maintenance records.

These data sources vary significantly in format, frequency, and operational context, making integration a foundational requirement. Standardized data schemas such as WITSML and PRODML reduce preprocessing complexity and improve interoperability across systems. A unified data plane enables seamless integration by consolidating structured and unstructured data into a shared environment.

Unified Data Plane for IT and OT Teams

A unified data plane is essential for aligning IT and OT teams. It creates a shared data layer where operational technology data from field systems and enterprise IT data coexist under consistent governance.

This eliminates data silos, improves cross-team visibility, and ensures machine learning models access synchronized and trusted datasets. By standardizing ingestion, storage, and access policies, the unified data plane supports scalable analytics without duplicating pipelines or storage layers across teams.

Data Quality, Labeling, and Storage

Centralized data lakes store historical and streaming data in native formats, enabling flexible experimentation and long-term model training. Supervised machine learning use cases in oil and gas require labeled datasets to detect patterns such as equipment failures or subsurface anomalies.

High data quality and reliable labeling directly impact model accuracy, operational confidence, and deployment success across exploration, drilling, and production workflows.

Data Sovereignty and Compliance

Data sovereignty requirements must be enforced across all machine learning environments. Oil and gas organizations often operate under regional regulations that restrict where data can be stored, processed, or transferred.

Machine learning platforms must support localized data residency, strict access controls, and auditable data flows. These capabilities ensure regulatory compliance while still enabling cross-region analytics when permitted by governance policies.

Compute and Processing Infrastructure

Machine learning workloads require infrastructure designed for compute-intensive training and continuous inference. High-performance computing environments use GPUs to accelerate model training on seismic, production, and sensor datasets.

While CPU-based systems handle data ingestion, orchestration, and deployment pipelines. This separation ensures efficient resource utilization across the machine learning lifecycle.

Edge, Storage, and Network Architecture

Edge computing infrastructure supports local inference at rigs, offshore platforms, and remote fields where connectivity is limited or intermittent. This reduces latency and allows models to operate autonomously during network disruptions.

High-speed storage systems enable efficient data movement between storage and compute resources. Network infrastructure must support high-bandwidth communication for clustered machine learning workloads while maintaining secure segmentation between operational and enterprise software.

Core Platforms and Operational Enablement

Dedicated machine learning data centers support large-scale experimentation and production-grade model training. Specialized software platforms connect operational data to predictive and optimization workflows.

Digital twins powered by machine learning simulate reservoir and equipment behavior, improving forecasting accuracy and operational planning across the oil and gas value chain. These components enable scalable, compliant, and reliable machine learning deployments in complex operational environments.

Challenges and Risks of Machine Learning in Oil and Gas Industry

Despite growing adoption, machine learning in oil and gas industry introduces technical, operational, and organizational risks that can directly impact safety, cost, and decision reliability. These risks are amplified by complex infrastructure, hazardous environments, and the critical nature of oil and gas operations.

Despite growing adoption, machine learning in oil and gas industry introduces technical, operational, and organizational risks that can directly impact safety, cost, and decision reliability. These risks are amplified by complex infrastructure, hazardous environments, and the critical nature of oil and gas operations.

Data Quality and Data Availability Issues

Machine learning models depend on large volumes of clean, consistent, and structured data. In practice, machine learning applications in oil and gas often rely on fragmented datasets stored across legacy systems and paper-based records. Poor data quality leads to unreliable predictions and costly operational errors.

Legacy Infrastructure Integration Risks

Many oil and gas assets operate on outdated control and monitoring systems. Integrating modern machine learning pipelines with legacy SCADA and operational platforms is technically complex and expensive. Poor integration increases failure risk during deployment and scaling.

Talent Shortages and Skill Gaps

Successful implementation requires expertise in both machine learning and petroleum engineering workflows. Most organizations struggle to find professionals with combined data science and domain-specific operational experience.

This slows adoption and increases dependency on external vendors. Webisoft helps companies overcome talent shortages by providing teams experienced in both machine learning and oil and gas workflows.

Our engineers understand drilling, production, and reservoir data alongside model development and deployment. Contact us to reduce dependency on fragmented vendors and shorten implementation timelines. challenges.

Build reliable machine learning systems for oil and gas with Webisoft.

Book a free consultation. Design, deploy, and scale production-ready machine learning solutions with domain-aligned experts.

Cultural Resistance to Model-Driven Decisions

Operational teams often hesitate to trust model outputs over established engineering judgment. Black-box model behavior reduces confidence in machine learning use cases in oil and gas decision-making. Resistance limits adoption and reduces potential performance gains.

High Initial Investment and ROI Pressure

Machine learning deployments require upfront spending on data infrastructure, compute resources, and training. Short-term return on investment is difficult to measure in complex operational environments. This slows executive buy-in and long-term planning.

Cybersecurity Exposure and Operational Risk

Connected machine learning systems expand the digital attack surface across assets. Compromised systems can disrupt operations, damage equipment, or halt production. Security failures pose direct financial and safety consequences.

Operational and Environmental Risk Amplification

Incorrect model outputs can affect drilling control, production optimization, or safety systems. In high-risk environments, small prediction errors may trigger cascading operational failures. Environmental damage and safety incidents remain critical concerns.

Erroneous Model Outputs and Misinterpretation

Machine learning models may generate misleading predictions when data conditions change. Blind reliance on outputs without human validation increases operational risk. This directly affects planning, drilling decisions, and reservoir forecasting.

Loss of Institutional Knowledge

Over-automation can reduce reliance on experienced engineers and operators. Without structured knowledge transfer, organizations risk losing critical operational expertise. This weakens long-term decision quality.

Ethical and Legal Considerations

Machine learning systems may reflect hidden biases in historical operational data. Data privacy, ownership, and regulatory compliance present legal risks across jurisdictions. Clear governance is required for machine learning for oil and gas operations.

How Webisoft Delivers Machine Learning in Oil and Gas Industry

Webisoft delivers real-world machine learning in oil and gas industry solutions grounded in deep project experience across data engineering, model deployment, and enterprise delivery. Our teams build, deploy, and support production-grade machine learning systems that transform operational workflows and unlock value from complex, heterogeneous oil and gas data.

Webisoft delivers real-world machine learning in oil and gas industry solutions grounded in deep project experience across data engineering, model deployment, and enterprise delivery. Our teams build, deploy, and support production-grade machine learning systems that transform operational workflows and unlock value from complex, heterogeneous oil and gas data.

Webisoft’s Approach to Oil and Gas ML Solutions

At Webisoft, every machine learning project begins with a business-driven discovery and feasibility analysis to align goals, metrics, and model scope.

We have delivered custom ML model development projects that tailor predictive models specifically for domain challenges such as predictive analytics, anomaly detection, and performance forecasting. Our approach ensures that systems do more than automate — they provide measurable operational improvements.

Data Engineering and Model Development

Webisoft’s data-first machine learning projects begin with clean, structured, and integrated datasets drawn from sensors, logs, and operational records. We build and train models using tailored algorithms optimized for precision and performance, not generic templates.

Examples of delivered work include ML models for predictive forecasting and anomaly detection systems, designed to anticipate failures or optimize production variables from real data.

Deployment, Monitoring, and Scalability

Webisoft has deployed machine learning projects in live production environments with full MLOps and model lifecycle management. Our implementations include automated monitoring, retraining pipelines, and performance dashboards that maintain model accuracy as operational conditions change. These deployments ensure models scale with growing datasets and evolving requirements.

Working with Engineers and Operations Teams

Across delivered projects, Webisoft collaborates directly with domain experts, drilling engineers, and operations teams. This collaboration strengthens model relevance, accelerates adoption, and translates ML insights into operational execution. Our delivered solutions integrate smoothly into daily workflows, providing actionable insights for field teams and decision makers.

Compliance, Reliability, and Long-Term Support

Webisoft machine learning projects are built with governance, explainability, and auditability as core components. Security and compliance are embedded through governance frameworks and access controls, ensuring trustworthy outputs. We provide long-term support and continuous optimization, so models evolve with your data, infrastructure, and operational goals.

Build reliable machine learning systems for oil and gas with Webisoft.

Book a free consultation. Design, deploy, and scale production-ready machine learning solutions with domain-aligned experts.

Conclusion

Machine learning in oil and gas industry is reshaping how companies analyze data, manage assets, and make operational decisions across exploration, production, and maintenance. Its value lies in practical outcomes such as improved forecasting, reduced downtime, safer operations, and more consistent performance under complex conditions.

However, success depends on data readiness, infrastructure maturity, and disciplined implementation aligned with real operational workflows. Webisoft supports this journey by delivering production-ready machine learning projects built around data engineering, deployment, and long-term system reliability.

FAQs

1. Can machine learning work with limited historical oil and gas data?

Yes, models can start with smaller datasets using feature engineering and transfer learning. Accuracy improves as more operational data becomes available.

2. Is machine learning suitable for small or mid-sized oil and gas operators?

Machine learning can be applied incrementally, starting with focused use cases. Smaller operators often begin with maintenance or production forecasting models.

3. How is machine learning different from traditional oilfield analytics?

Traditional analytics rely on fixed rules and assumptions. Machine learning adapts as data changes, improving predictions over time.

4. Can machine learning models adapt to different basins or fields?

Models require retraining or calibration for new geological conditions. Direct reuse without adjustment often reduces accuracy.

5. What skills should oil and gas teams develop for machine learning adoption?

Teams benefit from data literacy and basic model interpretation skills. Domain expertise remains essential for validating model outputs.